Introduction.

Welcome to the electrifying world of industrial motors, the driving force behind today’s high-tech manufacturing marvels. In this article, we delve deep into the diverse kingdom of industrial motors, where AC and DC motors engage in a powerful struggle for dominance. We explore their versatility, from micro to massive applications, uncovering their inner workings and the crucial roles played by the dynamic duo – the stator and rotor. Discover how electromagnetic principles guide their movements and the advanced control systems that ensure precision and efficiency. Furthermore, we’ll unveil their vital applications in automotive, aerospace, agriculture, food processing and the green revolution of renewable energy. Industrial motors are the unsung heroes powering the machinery that keeps our world in motion. Join us for an electrifying journey through this essential realm.

The Diversity of Industrial Motors.

In today’s high-tech manufacturing world industrial motors are the real stars. And these amazing electrical devices power various industries with their precision, efficiency and strength. Additionally there are different types of these motors each with special features and uses. Let’s explore the fascinating world of industrial motors.

A Glimpse into the Motor Kingdom.

In a realm dominated by motion, motors rule supreme. Within this Motor Kingdom AC and DC motors engage in an endless battle for power.

AC vs. DC: The Power Struggle.

AC with its polarity shifts is ideal for home gadgets and electricity networks. It’s like a flexible diplomat, fitting various jobs easily. DC provides a steady energy stream crucial for batteries and electronics. The battle goes on an energetic dance of innovation and use.

The Versatility of Electric Motors.

Electric motors are incredibly diverse with various types and sizes designed for specific tasks. They drive many things from household fans to complex industrial machinery making them crucial for various industries. Their adaptability is their key strength solidifying their role as a fundamental part of industrial operations.

Sizing it Up: From Tiny Servo Motors to Gigantic Generators.

Electric motors come in a wide range of sizes. There is small yet powerful servo motors used to stabilize smartphone cameras and there are large generators that produce electricity for cities. This size variety showcases the versatility of these machines.

Micro to Mini: Applications of Small-Scale Motors.

Tiny motors work in various applications. They’re crucial in medical devices like infusion pumps and ventilators and they help robots move precisely. These little wonders are like watch cogs ensuring industries run smoothly.

Heavy Hitters: Large Industrial Motors in Action.

In heavy industry, you’ll find powerful and robust motors. These giants run conveyor belts in mines, operate huge turbines in power plants and handle massive cargo containers at ports with massive cranes. Their strength and durability are impressive built to endure tough conditions.

The Inner Workings of Industrial Motors.

Within the world of industrial machinery industrial motors play a crucial role by efficiently transforming electrical energy into mechanical motion. These powerful workhorses are full of complex details.

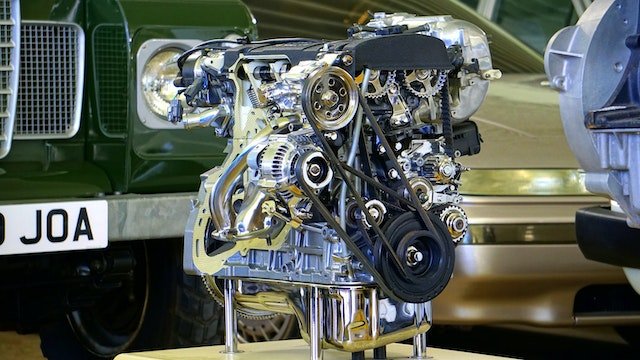

Exploring the Core Components.

In the core of every industrial motor lies a carefully designed set of parts all working together to convert electricity into physical energy. The stator and rotor are the powerhouses at the center of this complex machine.

Stator and Rotor: The Dynamic Duo.

The stator and rotor in a motor are like Batman and Robin. The stator the fixed part creates the magnetic field needed for motion using iron laminations. On the other hand, the rotor located at the motor’s center spins within the stator’s magnetic field. It’s made up of a shaft and conductive windings. When electricity flows through these windings it makes a magnetic field pushing and pulling the rotor making it move. This teamwork between the stator and rotor is what makes industrial motors work.

Electromagnetic Principles at Play.

Understanding industrial motor operation involves exploring electromagnetic principles. The stator and rotor rely on electromagnetism to function. When electricity flows through the stator it creates a magnetic field. The rotor equipped with conductive windings responds to these magnetic forces. It’s like an unseen force directing the motor’s movements, energizing it with each electrical surge.

Control Systems and Motor Efficiency.

Industrial motors are advanced machines that go beyond raw power. They’re finely tuned for control and efficiency. These motors need a precise control system to manage their speed, strength and direction effectively.

Inverters and Drives: Taming the Power.

To unleash the full potential of industrial motors inverters and drives step in. Inverters transform electrical power to match what the motor needs tweaking the frequency and voltage as necessary. Drives like conductors for the motor finely adjust its speed and direction aligning with the machinery’s demands. It’s a careful dance, just like a skilled conductor guiding an orchestra guaranteeing precise performance every step of the way.

The Quest for Energy Efficiency.

In today’s eco-aware world saving energy is a top priority for industrial motors. Engineers and designers are always working to make motors better using things like variable speed controls, super-efficient materials and smart designs. This helps cut down on wasted energy and is kinder to the environment.

Applications Across Industries.

Industrial motors are the unsung heroes that drive machinery in various sectors. They play a crucial role in keeping our world in motion. Let’s delve into the wide-ranging applications of industrial motors in different industries.

Manufacturing Marvels: Automotive and Aerospace.

The Role of Motors in Car Manufacturing.

In a car factory industrial motors power robotic arms for precise welding, assembling and painting. Moreover, Motors also move conveyor belts to keep car parts in sync on the assembly line making car manufacturing run smoothly.

Aerospace Innovation: Motors in the Sky.

Aerospace engineering uses various motors to make flying possible. These motors are crucial for safe and efficient air travel. They power commercial planes and control important parts like landing gear and flaps.

Feeding the World: Agriculture and Food Processing.

Precision Farming and Motor Technology.

In agriculture high-tech machines driven by GPS and advanced sensors are revolutionizing farming. Hence, these automated devices like tractors, combines and drones use powerful motors to precisely plant, grow and harvest crops. This boosts crop yields and saves resources.

From Field to Fork: Motors in Food Production.

In food factories industrial motors smoothly transforming raw ingredients into packaged goods. Where these motors drive conveyors, mixers and packaging machines guaranteeing the safety, efficiency and continuous availability of the food we enjoy.

Green Revolution: Renewable Energy and Industrial Motors.

Wind and Solar Power Generation.

The search for renewable energy sources has sparked a revolution with a focus on industrial motors. Wind turbines towering on wind farms use wind energy to make electricity. Solar power plants with solar panels trap sunlight to create power. Industrial motors help move panels and produce electricity in these systems.

Hydroelectric Energy: Turbines and Motors.

Hydropower relies on a tight partnership between motors and generators. Turbines crucial parts of hydroelectric plants spin thanks to water’s force changing movement into electricity. Big motors manage water flow and power production keeping a steady and green energy source.

Conclusion.

Industrial motors are the dynamic force driving progress across diverse industries. These powerhouses, from the versatile electric motors to the heavy-duty giants, are the backbone of modern manufacturing, aerospace, agriculture and renewable energy. Their intricate design, controlled by systems like inverters and drives, ensures efficiency and sustainability, aligning with our eco-conscious world’s needs. As motors continue to evolve and adapt, they remain the unsung heroes, tirelessly propelling innovation and advancement, enabling our world to move forward with precision, strength and eco-friendliness.