Unlock the secrets of generator wiring in this guide! From installation to troubleshooting, learn everything you need to know for smooth power backup.

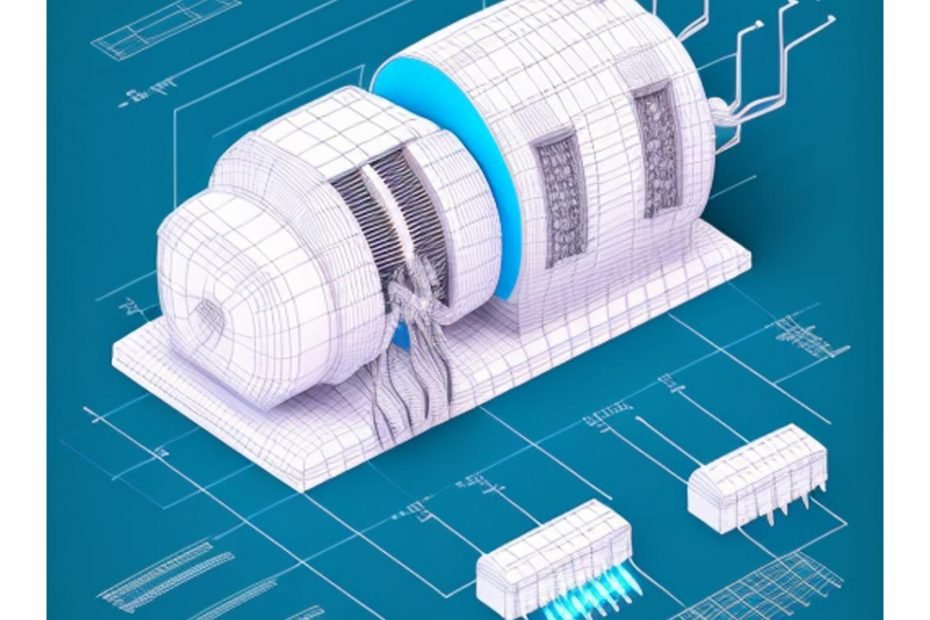

Generator Wiring Components.

When it comes to generator wiring, understanding the crucial role of various components in the proper functioning and safety of the generator system. Let us explore the key components of generator wiring and their significance in ensuring a reliable and efficient power supply.

Main Power Input.

It is the connection point where the generator receives the electrical power it needs to generate electricity. Where it serves as the portal for the external power source, with the necessary mechanical energy such as a fuel-powered engine or a renewable energy system. It is typically equipped with connectors or terminals designed to establish a secure and reliable connection between the generator and the power source.

Control Panel and Switches.

This is the nerve interior of the generator. Where it houses various switches, gauges, and indicators that allow to monitor and control the generator’s operation. These controls enable users to start or stop the generator, adjust the voltage or frequency output, and monitor crucial parameters such as oil pressure, engine temperature, and fuel level. The control panel provides a user-friendly interface to manage the performance of the generator and ensure it operates within safe limits.

Automatic Transfer Switches (ATS).

ATS serve as the interface between the generator and the main electrical panel of a building. ATS detects the loss of utility power and automatically transfers the load from the main power supply to the generator during a power outage. This seamless transition ensures uninterrupted power supply to critical circuits or the entire electrical system. ATS also monitors the utility power and automatically transfers the load back to the main power source when it is restored.

Circuit Breakers and Fuses.

Circuit breakers and fuses protect the generator system from overloads and short circuits. They are responsible for interrupting the flow of electrical current when an abnormal condition occurs, preventing potential damage to the generator and electrical equipment. Circuit breakers are automatic switches that trip when the current exceeds their evaluated capacity. Whereas fuses contain a thin metal wire that melts when excessive current passes through them. Both circuit breakers and fuses are essential in maintaining the integrity of the generator wiring and preventing electrical hazards.

Voltage Regulators.

Voltage regulators maintain a stable and consistent voltage output from the generator. Ensuring the electrical devices connected to the generator receive the required voltage levels, regardless of fluctuations in the input power or varying loads. These monitor the output voltage and make necessary adjustments to maintain a steady voltage within an acceptable range. This component is particularly vital when powering sensitive electronic equipment that requires precise voltage levels to operate efficiently and prevent damage.

Generator Wiring Types.

There are different types to consider based on our specific needs and circumstances. Understanding these generator wiring types is crucial in determining the most suitable setup for our power requirements. Here, let’s explore three common generator wiring types: standby generator wiring, portable generator wiring, and hybrid generator wiring.

01. Standby Generator Wiring.

This involves connecting a generator directly to the main electrical panel of a building or home. Where this setup is designed to provide backup power during utility outages and ensure uninterrupted electricity supply. Standby generators are typically permanently installed and automatically activated when the utility power fails. They are equipped with ATS.

The installation process for standby generator wiring involves connecting the generator to the main electrical panel using a dedicated transfer switch. That ensures that the generator’s power is isolated from the utility grid to prevent any back feeding, which can pose safety risks to utility workers. Also, load balancing and power management techniques may be employed to prioritize power distribution to critical circuits during an outage.

02. Portable Generator Wiring.

This offers flexibility and versatility in providing temporary power in various situations. These are typically smaller in size and can be easily carried from one location to another. They are commonly used in outdoor events, construction sites, or as a temporary power source for homes during emergencies.

Portable generator wiring involves utilizing extension cords to connect the generator directly to appliances, devices, or tools. The wiring setup requires careful consideration of the power requirements of the connected devices and the appropriate gauge and length of extension cords to ensure safe and efficient power transmission. It’s crucial to follow proper grounding practices to prevent electrical hazards.

03. Hybrid Generator Wiring.

Hybrid generator wiring involves integrating multiple power sources. This type of wiring setup is particularly useful in situations where a combination of renewable energy sources that are utilized.

Hybrid generator wiring enables seamless switching between the different power sources based on factors like availability, demand, and system preferences. Advanced control systems and power management technologies are employed to automatically prioritize and balance the power from each source. This ensures optimal utilization of renewable energy and minimizes reliance on the generator, leading to increased energy efficiency and cost savings.

Generator Wiring Safety.

When it comes to generator wiring, safety should be a top priority. Proper installation and adherence to safety guidelines are vital to avoid electrical hazards. And ensure the efficient and reliable operation of our generator system. Let’s explore key aspects of generator wiring safety.

Importance of Proper Grounding.

This is essential in generator wiring to protect against electrical faults and provide a safe path for electrical current to dissipate. Grounding helps prevent electric shocks, electrical fires, and damage to equipment. A properly grounded generator system ensures that any extra electrical energy is carefully discharged into the ground, minimizing the risk of electrical hazards.

Electrical Codes and Regulations.

Adhering to electrical codes and regulations is critical for ensuring the safety and compliance of generator wiring installations. These codes and regulations provide guidelines on proper wiring practices, equipment selection, and safety measures. They are designed to protect individuals, properties, and the overall electrical system. It is important to consult with local authorities or a qualified electrician to ensure compliance with the specific codes and regulations in our area.

Using Appropriate Wire Sizes and Gauges.

Appropriate usage of wire sizes and gauges is essential to prevent overheating, voltage drops, and potential hazards. Undersized wires can result in excessive resistance and generate heat, which can lead to wire insulation damage or even fires. Meanwhile, oversized wires, on the other hand, maybe unnecessary and can increase installation costs. It is crucial to consult wiring charts or seek guidance from professionals to determine the correct wire sizes and gauges based on the generator’s capacity and the estimated load.

Avoiding Overload and Short Circuits.

Overloading occurs when the total electrical load connected to the generator exceeds its evaluated capacity. This can lead to overheating, voltage drops, and potential damage to the generator and connected devices. Short circuits, on the other hand, occur when there is an unintended connection between the hot and neutral wires, resulting in excessive current flow. This can cause circuit breakers to trip or fuses to blow, and in the worst cases, lead to electrical fires. It is very important to properly calculate the estimated load and ensure that it does not exceed the generator’s capacity.

Safety Precautions During Installation and Maintenance.

Proper safety precautions during installation and maintenance are essential to protect individuals and maintain the integrity of the generator wiring system. It is crucial to disconnect the generator from the power source before performing any work. In addition, wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses, can prevent injuries. Regular maintenance, including inspections, cleaning, and testing, should be conducted according to the manufacturer’s recommendations and guidelines.

Troubleshooting Common Generator Wiring Issues.

Generator wiring issues can be frustrating and disruptive, but with proper troubleshooting techniques, we can quickly identify and resolve common problems.

No Power Output.

One of the most common generator wiring issues is a lack of power output. If our generator is running but not producing electricity, there are several potential causes to consider. Start by checking the generator’s fuel level and ensuring that the engine is running smoothly. Next, inspect the generator’s voltage regulator, which regulates the output voltage. A faulty or malfunctioning voltage regulator can result in no power output. Additionally, examine the generator’s wiring connections, ensuring that they are secure and free from corrosion or damage.

Circuit Breaker Tripping.

If our generator’s circuit breaker keeps tripping, it indicates an overload or short circuit within the electrical system. Start by checking the connected devices and appliances to ensure they are not exceeding the generator’s capacity. Remove any unnecessary loads and distribute the electrical load evenly. Inspect the circuit breakers themselves, as a faulty breaker can also cause frequent tripping.

Voltage Fluctuations.

Voltage fluctuations can occur in generator systems, leading to unstable or inconsistent power output. If you notice flickering lights or erratic behaviour in your electrical devices, voltage fluctuations may be the cause. Start by checking the generator’s fuel supply and ensuring that it is running at the proper speed. Improper engine speed can result in voltage irregularities. Next, examine the generator’s voltage regulator and automatic voltage regulator (AVR) if equipped. These components regulate the voltage output and may require adjustment or replacement if they are malfunctioning.

Grounding Problems.

If we are experiencing grounding problems, it is important to address them promptly. Check the generator’s grounding connection and ensure that it is properly connected to a grounding electrode, such as a grounding rod. Inspect the grounding wire for any signs of damage or corrosion. Additionally, ensure that the grounding connection meets local electrical codes and regulations.

ATS Malfunctions.

If we encounter ATS malfunctions, such as failure to transfer the load or incorrect switching, it is important to address them promptly. Start by inspecting the ATS wiring connections, ensuring they are secure and free from damage. Check for any error codes or indicators on the ATS control panel that may provide information about the malfunction.

Make sure to consult a qualified technician or electrician with expertise if they diagnose and resolve no power output problem, assess the wiring and make any necessary repairs or upgrades, inspection and troubleshooting or in ATS troubleshooting and repair.

Conclusion.

By demystifying generator wiring and equipping ourselves with the knowledge and understanding of its components, types, safety measures, and troubleshooting techniques, we can ensure a smooth and reliable power backup experience, providing peace of mind during utility outages or emergencies.